Free sample for Ultrasonic Liquid Fuel Level Sensor - Online PH ORP Sensor – JIRS Detail:

Pls unpack and check that the sensor has been supplied undamaged and that it is the correct option as ordered. If you have any problems please contact your supplier.

Introduction

PH/ORP composite electrode is made from low impedance sensitive glass membrane, can be applied to measure PH value in various conditions, has quick response, good thermal stability characteristics. With good reproducibility, not easy to hydrolysis, eliminate the alkali error basically, appear a linear power value in 0-14 measuring range. The reference system composed of gel electrolyte salt bridge and Ag/Agcl has the stable half cell potential and good contamination resistance character. The circular PTFE diaphragm is not easy to block, can be used for long-term online measuring.

Main technique specification

|

Name |

Function |

|

Measuring Range |

0-14ph, -1900~+1900mV |

|

Accuracy |

pH: ±0.01 pH, ORP± 1Mv |

|

Measured temperature |

0-60℃, normal temp. 60℃-100℃, high temp. |

|

Response time |

5sec |

|

Driftance |

≦0.02PH/24hours |

|

Sensitive membrane impedance |

≦200*106Ω |

|

Slop |

≧98 % |

|

Electrode equipotential point |

7±0.5PH |

|

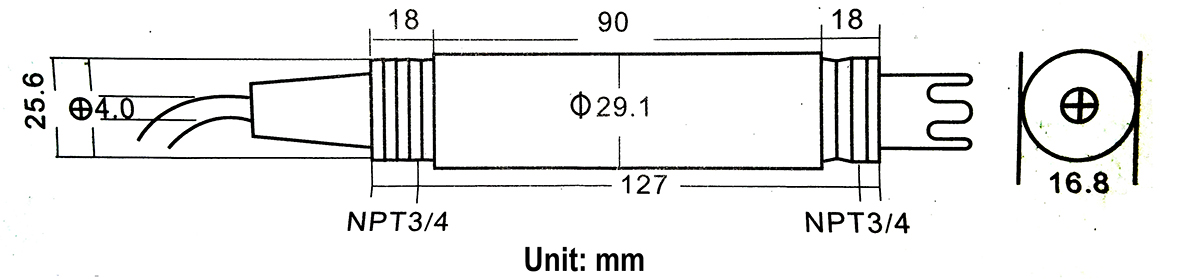

Outline connect dimension |

NPT 3/4” thread |

|

Body main material |

PP – normal temp., Glass- high temp. |

|

Wetted material |

PP material cover, impedance sensitive glass membrane, circular PTFE diaphragm, and gel electrolyte salt bridge. |

|

Flow rate |

Not more than 3m/s |

|

Working pressure |

0-0.4mPa |

|

Joint way |

BNC connector or Pin connector |

|

ATC |

PT 100, PT1000, NTC 10K |

|

Calibration |

4.00, 6.86, 9.18 powder |

|

Cable length |

5meter or as per request. |

Outline dimensions

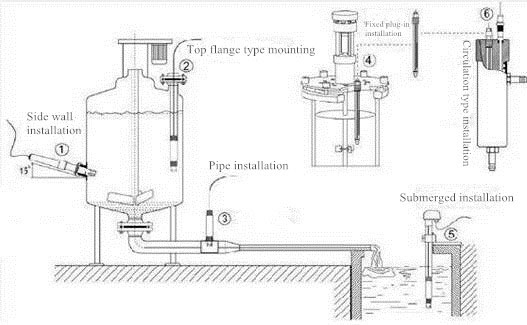

Installation method and Attention-matter

(Several common method of installation)

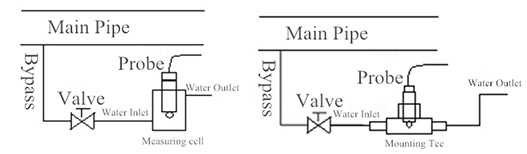

In order to make sure the probe measure the real value on the pipe, bubbles should be avoided, otherwise the value will be not accurate, please install according to the following chart:

Note

1. The probe bypass pipe of the main pipe, valve should be installed in front of it to control the water flow speed, flow should be relatively slow, generally there are steady water flow out of the outlet port is ok. The probe should be installed vertically and should be insert into the active water flow, outlet port should be higher than inlet port which could make sure the probe was in the water solution absolutely.

2. The probe should be calibrated before installation.

3. The measure signal is weak electric signal, its cable should be contributed separately, it is not allowed to contributed together in same cable or terminal with other power line, control line etc, which it to avoid interrupt or broke the measure unit.

4.If the measure cable should be length, please contact with the supplier or indicated before place order (generally not longer than 10m).

Operation and maintenance

1). Before measuring, the PH electrode must calibrate in the known PH value standard buffer solution, in order to improve the accuracy of measurement, the buffer solution PH value must be reliable and close to the measured PH value, the closer the better, generally not more than three PH value.

2). The sensitive glass ball bubble of electrode front-end can not contact with hard objects, any breakage and brush hair will disable electrode.

3). Electrode socket must maintain clean and dry, if there is any defile, need to wipe clean and dry by medical cotton and anhydrous alcohol. Absolutely prevent output two end short circuit, otherwise will lead to a measurement misalignment or failure.

4). Before measuring, pls pay attention to getting rid of bubbles in the glass ball, otherwise will cause measurement error. During measuring, electrode in the test solution should be still placed after agitation, to speed up the response.

5). Measured before and after measurement, need to clean the electrode by using deionized water, to ensure the accuracy of measurement. After measuring the thick solution, the electrode need to be washed solvent by deionized water.

6). After long-term use,the electrode will generate passivation, the phenomenon is sensitive gradient will be lower, slow response, inaccuracy reading. In this situation, the electrode bottom ball bubble need to immerse into the 0.1M solution for 24 hours, (0.1M dilute hydrochloric acid preparation: 9ml hydrochloric acid is diluted to 1000ml with distilled water), and then immerse the electrode bottom ball bubble into the 3Mkcl solution a few hours, make it restore performance.

7). Glass ball bubble pollution or liquid junction congestion would also cause the electrode passivation, in this situation, need to wash with the appropriate cleaning solution according to the nature of pullutants (for reference).

|

Pullutants |

Detergent |

|

Inorganic metal oxides |

Lower 1M dilute hydrochloric acid |

|

Organic oil content |

Diluted detergent ( weak alkaline) |

|

Resin substance |

Dilute alcohol, acetone, ethyl ether |

|

Protein blood deposit |

Acidic enzyme solution (such as pepsin, etc) |

|

Pigment category substance |

Diluted bleach solution, hydrogen peroxide |

8). The electrode use cycle is one year or so, the aging electrode should be replaced timely.

Joint wire

Transparent wire -INPUT

Black wire-REF

White wire-TEMP (if have temperature compensation)

Green wire-TEMP (if have temperature compensation)

JiShen Water treatment Co., Ltd.

Add: No.18, Xingong Road, High-Technology Area, Shijiazhuang,China

Tel: 0086-(0)311-8994 7497 Fax: (0)311-8886 2036

E-mail: info@watequipment.com

Website: www.watequipment.com

Product detail pictures:

Related Product Guide:

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for Free sample for Ultrasonic Liquid Fuel Level Sensor - Online PH ORP Sensor – JIRS , The product will supply to all over the world, such as: Estonia, Florence, Rome, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.