Pls unpack and check that the sensor has been supplied undamaged and that it is the correct option as ordered. If you have any problems please contact your supplier.

Application

Widely used for industrial water, tap water, cooling water, pure water etc. Conductivity measurement.

Main technique specification

|

Name |

Function |

|

Cell Constant |

0.05cm-1 ( v ) 0.1cm-1 ( ) 1.0cm-1 ( ) 10.0cm-1 ( ) |

|

Electrode structure |

Bipolar |

|

Electrode material |

ABS ( ) 316L Stainless steel( v ) |

|

Temperature Sensor |

NTC 10K ( v ) Pt 1000 ( ) Pt 100 ( ) |

|

Thread structure |

½” NPT Thread |

|

Working pressure |

0~0.5MPa |

|

Operating temperature |

0~50℃ |

|

Cable length |

Standard:5m or others(5-30m) |

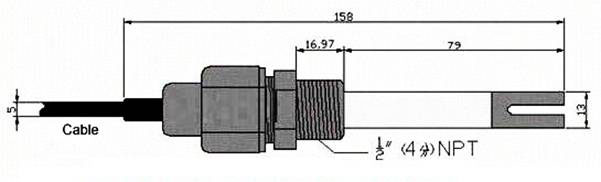

Dimensions drawing

Conductivity(TDS)/ Resistivity electrode dimensions

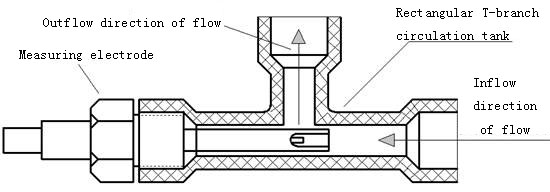

Installation and maintenance

Installation: To ensure the real measurement result, data distortion caused by air bubble or dead water in conductance cell should be avoided. The installation should be performed strictly according to the following drawing:

Notes

1. The electrode should be installed at a lower location in the pipe where the flow speed is steady and air bubbles are seldom generated.

2. No matter the conductance cell is horizontally or vertically installed, it should be deeply inserted into the moving water.

3. The conductivity/Resistivity signal is weak electronic signal and its collecting cable should be separately installed.

When threading cable joint or connecting terminal board is used, to avoid wetting interference or breakdown of measurement unit circuit, they should not be connected to the same group of cable joint or terminal board with the power or control line.

4. When the measurement cable needs to be lengthened, it’s recommended to use the cable provided by the original manufacturer, and the joint should be subject to reliable damp-proofing insulation disposal. When a longer distance is involved, the length of the cable (<30m) should be agreed on before delivery, and if the length is over 30m, a transmitter should be used.

Electrode Maintenance

1. The electrode cell should not be soaked in strong acid or alkali liquid, and the platinum black coating should not be wiped or it will lead to electrode surface damage and the constant and response capability will be affected. The right way should be: when the electrode is dirty, soak it in 10% dilute hydrochloric acid for a short while, then rinse it with pure water to keep the surface clean.

2. The measurement cable is special cable and should not be changed at will or it will cause significant error.

Joint wire

white wire to Cell -INPUT

Yellow wire to Cell -OUPUT

Black wire-TEMP

Red wire-TEMP

JiShen Water treatment Co., Ltd.

Add: No.18, Xingong Road, High-Technology Area, Shijiazhuang,China

Tel: 0086-(0)311-8994 7497 Fax:(0)311-8886 2036

E-mail:info@watequipment.com

Website: www.watequipment.com